ATOM-V

V-Series

- Low-height base design with advanced concept and technology of mold clamping connection and injection unit (Patent No: 10-1465475 10-1471360)

- Minimal installation space with compact design.

- Safety Door for user convenience.

- Energy saving(65~75%) by RPM control of the Servo motor.

- Perfect CLOSED LOOP control by new technology controller.

- Up Down Clamping way by center press way and vertical injection way

- High accuracy clamping force control by pressure sensor.

- Suitable design for Hoop molding and automation system.

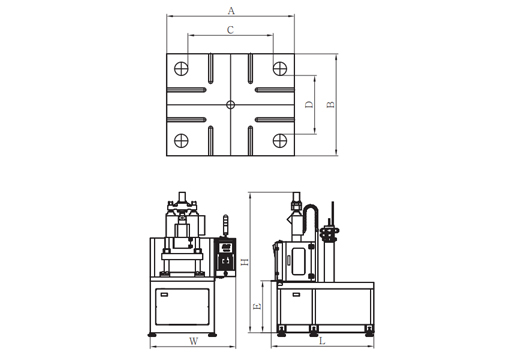

| A x B | C x D | E | W x Lx H | |

| ATOM 35 | 500x390 | 360x250 | 880 | 1285x1580x2535 |

| ATOM 60 | 640x460 | 410x280 | 940 | 1335x1710x2780 |

| ATOM 80 | 670x510 | 460x310 | 1000 | 1385x1740x2890 |

| ATOM 100 | 745x565 | 520x340 | 1010 | 1495x1855x2900 |

| ATOM 120 | 795x615 | 565x365 | 1160 | 1535x2025x3675 |

| ATOM 150 | 910x730 | 660x480 | 1280 | 1780x2380x4060 |

| ATOM 200 | 1050x790 | 760x500 | 1380 | 1940x2540x4330 |

SPECIFICAION

| ATOM-35V | ATOM-60V | ATOM-80V | ATOM-100V | ATOM-120V | ATOM-150V | ATOM-200V | |||||||||||||||||

| I n j e c t i o n |

Screw Type | Unit | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B |

| Screw Diameter | 18 | 22 | 25 | 22 | 25 | 28 | 25 | 28 | 32 | 28 | 32 | 36 | 32 | 36 | 40 | 36 | 40 | 45 | 40 | 45 | 50 | ||

| Injection Pressure |

kg/ ㎠ |

3780 | 2531 | 1960 | 3240 | 2500 | 2000 | 2923 | 2330 | 1784 | 4678 | 2050 | 1620 | 2631 | 2079 | 1684 | 2598 | 2104 | 1662 | 2800 | 2212 | 1792 | |

| Injection Capacity |

㎤ | 25 | 38 | 49 | 49 | 63 | 80 | 63 | 80 | 104 | 80 | 104 | 132 | 160 | 203 | 251 | 203 | 251 | 318 | 276 | 350 | 431 | |

| Injection Rate | ㎤/ sec |

31 | 46 | 59 | 57 | 74 | 93 | 64 | 80 | 130 | 87 | 113 | 144 | 115 | 145 | 180 | 134 | 166 | 210 | 166 | 210 | 260 | |

| Plasticzing Capacity |

kg/ hr |

15.3 | 22.9 | 28.1 | 22.9 | 28.1 | 30.4 | 28.1 | 30.3 | 34.8 | 36.4 | 43.6 | 48.5 | 52.3 | 57.3 | 68.1 | 59.5 | 68.1 | 78.3 | 79.1 | 97.9 | 142.4 | |

| Screw Revolution |

rpm | 0~350 | 0~350 | 0~300 | 0~300 | 0~280 | 0~280 | 0~250 | |||||||||||||||

| C l a m p i n g p a r t s |

Mold Clamping Foorce |

ton | 35 | 60 | 80 | 100 | 120 | 150 | 200 | ||||||||||||||

| max' Mold Plate Distance |

mm | 410 | 470 | 520 | 570 | 600 | 650 | 850 | |||||||||||||||

| Clamping Stroke | mm | 230 | 270 | 320 | 320 | 350 | 350 | 500 | |||||||||||||||

| Mold Thickness | mm | 180 | 200 | 200 | 250 | 250 | 300 | 350 | |||||||||||||||

| Tie-Bar Distance | mm | 360 x 250 | 410 x 280 | 460 x 310 | 520 x 340 | 565 x 365 | 660 x 480 | 760 x 500 | |||||||||||||||

| Mold Platen Size |

mm | 500 x 390 | 640 x 460 | 670 x 510 | 745 x 565 | 795 x 615 | 910 x 730 | 1050 x 790 | |||||||||||||||

| Ejector Stroke | mm | 50 | 50 | 60 | 60 | 80 | 80 | 80 | |||||||||||||||

| G e n e r a l s |

Capacity of Motor |

kw | 11 | 11 | 15 | 15 | 18 | 22 | 30 | ||||||||||||||

| Capacity of Heater |

kw | 3.7 | 4.5 | 5 | 5 | 7 | 7 | 7 | |||||||||||||||

| Oil Tank Capacity |

L | 150 | 180 | 230 | 230 | 300 | 300 | 350 | |||||||||||||||

| Machine Size(WxLxH) | m | 0.95x1.58x2.03(2.53) | 1.00x1.61x2.19(2.78) | 1.05x1.64x2.27(2.91) | 1.16x1.76x2.32(2.96) | 1.20x1.93x2.88(3.67) | 1.46x2.38x3.31(4.06) | 1.60x2.54x3.69(4.33) | |||||||||||||||

| Machin Weight | ton | 2.6 | 3.3 | 3.8 | 4.2 | 5.5 | 6.5 | 8 | |||||||||||||||

- This pecification are subject to change without ptioi notice for quality improvement.