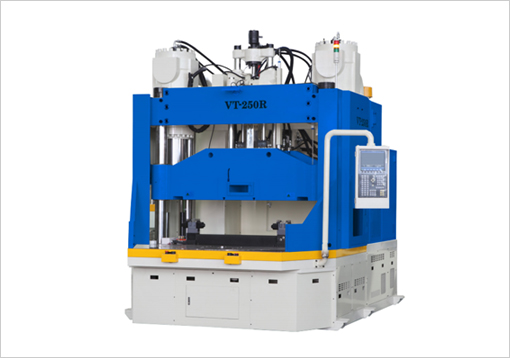

ATOM-VTR

VTR-Series

- Low-height special injection machine equipped with all vertical clamping and injection structures and rotary table

- Environment-friendly high-speed, high-precision insert injection molding

· Hybrid control system (servo motor + pump)

· Electric motor-operated rotational system

· Hybrid ejecting system

· Accumulator plus high-speed circuit

- High-quality high-performance screw and barrel

· Anti-corrosion & anti-wearing screw & barrel with HB200 500 800 series bi-metallic materials

- MC 7000 controller with touch-screen

· Closed-loop control

· Precise reproduction and rapid response contro

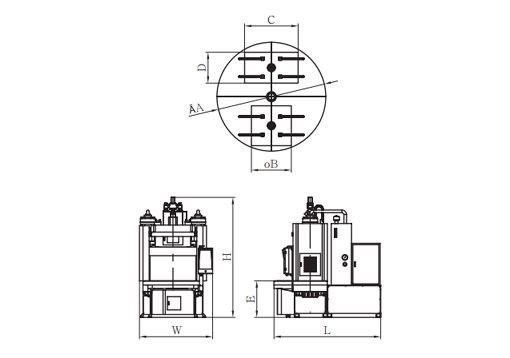

| A | □ B | C x D | E | W x Lx H | |

| ATOM VT 80R | Ø1000 | □ 380 | 510 x 350 | 800 | 1460 x 2250 x 2910 |

| ATOM VT 100R | Ø1030 | □ 430 | 530 x 400 | 800 | 1560 x 2250 x 2910 |

| ATOM VT 120R | Ø1100 | □ 460 | 590 x 430 | 865 | 1940 x 3080 x 3050 |

| ATOM VT 150R | Ø1100 | □ 550 | 710 x 480 | 865 | 2140 x 3190 x 3130 |

| ATOM VT 200R | Ø1200 | □ 590 | 770 x 500 | 885 | 2200 x 3280 x 4110 |

| ATOM VT 250R | Ø1200 | □ 640 | 790 x 550 | 875 | 2350 x 2840 x 4460 |

| ATOM VT 300R | Ø1500 | □ 680 | 870 x 570 | 850 | 2540 x 3640 x 4590 |

| ATOM VT 350R | Ø1500 | □ 730 | 940 x 620 | 1040 | 2710 x 3680 x 4830 |

| ATOM VT 400R | Ø1800 | □ 730 | 940 x 620 | 1040 | 2750 x 3680 x 4830 |

| ATOM VT 450R | Ø1800 | □ 800 | 1020 x 680 | 1040 | 3240 x 3940 x 5380 |

| ATOM VT 500R | Ø1800 | □ 800 | 1020 x 680 | 1040 | 3290 x 3940 x 5380 |

SPECIFICAION

| AT0M-VT 80R | AT0M-VT 100R | AT0M-VT 120R | AT0M-VT 150R | AT0M-VT 200R | AT0M-VT 250R | AT0M-VT 300R | AT0M-VT 350R | AT0M-VT 400R | AT0M-VT 450R | AT0M-VT 500R | |||||||||||||||||||||||||

| I n j e c t i o n |

Screw Type |

Unit | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B |

| Screw Diameter |

25 | 28 | 32 | 28 | 32 | 36 | 32 | 36 | 40 | 36 | 40 | 45 | 40 | 45 | 50 | 45 | 50 | 55 | 50 | 55 | 60 | 55 | 60 | 65 | 55 | 60 | 65 | 60 | 65 | 70 | 60 | 65 | 70 | ||

| Injection Pressure |

kg/ ㎠ |

2923 | 2330 | 1784 | 2678 | 2050 | 1620 | 2631 | 2079 | 1684 | 2598 | 2104 | 1662 | 2800 | 2212 | 1792 | 2613 | 2116 | 1749 | 2318 | 1916 | 1610 | 2154 | 1810 | 1542 | 2154 | 1810 | 1542 | 2138 | 1822 | 1571 | 2138 | 1822 | 1571 | |

| Injection Capacity |

㎤ | 63 | 80 | 104 | 80 | 104 | 132 | 160 | 203 | 251 | 203 | 251 | 318 | 276 | 350 | 431 | 349 | 431 | 522 | 490 | 593 | 706 | 593 | 706 | 829 | 593 | 706 | 829 | 791 | 928 | 1077 | 791 | 928 | 1077 | |

| Injection Rate |

㎤/ sec |

64 | 80 | 130 | 87 | 113 | 144 | 115 | 145 | 180 | 134 | 166 | 210 | 166 | 210 | 260 | 205 | 253 | 306 | 251 | 304 | 362 | 270 | 322 | 378 | 270 | 322 | 378 | 327 | 384 | 445 | 327 | 384 | 445 | |

| Plasticzing Capacity |

kg/ hr |

28.1 | 30.3 | 34.8 | 36.4 | 43.6 | 48.5 | 52.3 | 57.3 | 68.1 | 59.5 | 68.1 | 78.3 | 79.1 | 97.9 | 142 | 114 | 161 | 195 | 173 | 210 | 234 | 210 | 234 | 275 | 210 | 234 | 275 | 273 | 320 | 349 | 273 | 320 | 349 | |

| Screw Revolution |

rpm | 0~300 | 0~300 | 0~280 | 0~280 | 0~250 | 0~250 | 0~240 | 0~240 | 0~240 | 0~240 | 0~240 | |||||||||||||||||||||||

| C l a m p i n g p a r t s |

Mold Clamping Foorce |

ton | 80 | 100 | 120 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | ||||||||||||||||||||||

| max' Mold Plate Distance |

mm | 520 | 570 | 600 | 650 | 850 | 850 | 900 | 950 | 950 | 1150 | 1150 | |||||||||||||||||||||||

| Clamping Stroke |

mm | 320 | 320 | 350 | 400 | 500 | 500 | 500 | 550 | 550 | 650 | 650 | |||||||||||||||||||||||

| Mold Thickness |

mm | 200 | 250 | 250 | 300 | 350 | 350 | 400 | 400 | 400 | 500 | 500 | |||||||||||||||||||||||

| Turn Table Diameter |

mm | Ø1000 | Ø1100 | Ø1200 | Ø1400 | Ø1500 | Ø1600 | Ø1700 | Ø1800 | Ø1800 | Ø2000 | Ø2000 | |||||||||||||||||||||||

| Ejector Stroke |

mm | 70 | 70 | 80 | 80 | 100 | 100 | 120 | 120 | 150 | 150 | 150 | |||||||||||||||||||||||

| G e n e r a l s |

Capacity of Main Motor |

kw | 11+3.5 | 15+3.5 | 18+5 | 22+5 | 30+5 | 33+7.5 | 37+7.5 | 43+7.5 | 43+7.5 | 50+11 | 56+11 | ||||||||||||||||||||||

| Capacity of Ejector Motor |

kw | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 5.5 | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | |||||||||||||||||||||||

| Capacity of Heater |

kw | 5 | 5 | 7 | 7 | 7 | 15 | 15 | 15 | 15 | 18 | 18 | |||||||||||||||||||||||

| Oil Tank Capacity |

L | 230 | 230 | 450 | 450 | 580 | 680 | 720 | 870 | 870 | 1000 | 1000 | |||||||||||||||||||||||

| Machine Size (WxLxH) |

m | 1.23x2.25x2.27 (2.91) |

1.58x2.51x2.51 (3.01) |

1.72x3.08x2.49 (3.05) |

1.95x3.19x2.58 (3.13) |

2.08x3.28x3.19 (4.11) |

2.12x2.84x3.49 (4.46) |

2.40x3.54x3.79 (4.59) |

2.49x3.68x3.86 (4.83) |

2.54x3.68x4.50 (4.93) |

3.12x3.94x4.80 (5.38) |

3.12x3.94x4.80 (5.38) |

|||||||||||||||||||||||

| Machin Weight |

ton | 7 | 7.5 | 10 | 12 | 14 | 16 | 22 | 26 | 28 | 33 | 34 | |||||||||||||||||||||||

- 본 사양은 제품의 품질 향상을 위하여 예고 없이 변경될 수 있습니다.