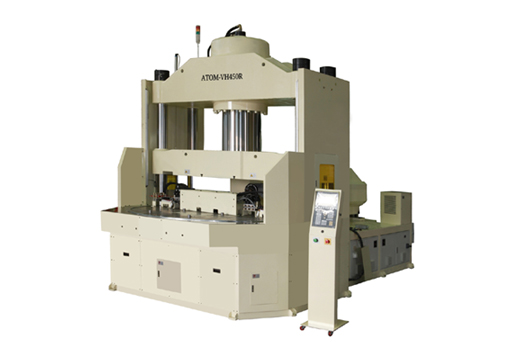

ATOM-VHR

VHR-Series

- Vertical hydraulic clamping and horizontal injection system with the rotational bed.

- One up mold and two down molds, generating high production capacity.

- Spacious working area for higher productivity.

- Easy to maintain and repair the nozzle and screw.

- More than 120 tons : With 4 tie-bars

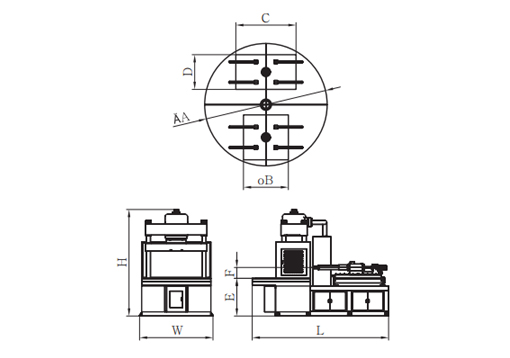

| A | □ B | C x D | E | F | W x Lx H | |

| ATOM VH 60R | 1000 | □ 380 | 510 x 350 | 950 | 175±25 | 1735 x 3230 x 2390 |

| ATOM VH 80R | 1100 | □ 430 | 530 x 400 | 950 | 175±25 | 1855 x 3360 x 2410 |

| ATOM VH 100R | 1100 | □ 430 | 530 x 400 | 950 | 175±25 | 1855 x 3360 x 2720 |

| ATOM VH 120R | 1200 | □ 460 | 590 x 430 | 1030 | 230±30 | 1995 x 3890 x 3050 |

| ATOM VH 150R | 1400 | □ 550 | 710 x 480 | 1030 | 230±30 | 2225 x 4090 x 2930 |

| ATOM VH 200R | 1500 | □ 590 | 770 x 500 | 1030 | 300±50 | 2395 x 4450 x 3025 |

| ATOM VH 250R | 1500 | □ 590 | 770 x 500 | 1100 | 350±50 | 2345 x 4760 x 3630 |

| ATOM VH 300R | 1800 | □ 730 | 940 x 620 | 1100 | 350±50 | 2645 x 4930 x 3900 |

| ATOM VH 450R | 2260 | □ 880 | 1140 x 720 | 1170 | 400±50 | 3215 x 5610 x 3980 |

SPECIFICAION

| AT0M-VH 60R | AT0M-VH 80R | AT0M-VH 100R | AT0M-VH 120R | AT0M-VH 150R | AT0M-VH 200R | AT0M-VH 250R | AT0M-VH 300R | AT0M-VH 450R | |||||||||||||||||||||

| I n j e c t i o n |

Screw Type |

Unit | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B | Y | A | B |

| Screw Diameter |

22 | 25 | 28 | 25 | 28 | 32 | 28 | 32 | 36 | 32 | 36 | 40 | 36 | 40 | 45 | 40 | 45 | 50 | 45 | 50 | 55 | 50 | 55 | 60 | 55 | 60 | 65 | ||

| Injection Pressure |

kg/ ㎠ |

2936 | 2273 | 1812 | 2688 | 2142 | 1640 | 2491 | 1907 | 1506 | 2481 | 1960 | 1588 | 2873 | 2327 | 1839 | 2690 | 2125 | 1722 | 2333 | 1890 | 1562 | 2329 | 1925 | 1617 | 2249 | 1890 | 1610 | |

| Injection Capacity |

㎤ | 60 | 78 | 98 | 78 | 98 | 128 | 98 | 128 | 162 | 128 | 162 | 201 | 203 | 251 | 317 | 270 | 341 | 421 | 341 | 422 | 510 | 647 | 783 | 932 | 783 | 932 | 1094 | |

| Injection Rate |

㎤/ sec |

63 | 82 | 103 | 69 | 87 | 113 | 93 | 122 | 154 | 122 | 154 | 191 | 121 | 150 | 190 | 173 | 219 | 271 | 250 | 308 | 373 | 230 | 278 | 331 | 331 | 370 | 434 | |

| Plasticzing Capacity |

kg/ hr |

19.5 | 28.1 | 30.3 | 28.1 | 30.3 | 34.8 | 36.4 | 43.6 | 48.5 | 52.3 | 57.3 | 68.1 | 59.5 | 68.1 | 78.3 | 79.1 | 97.9 | 142.4 | 113.6 | 160.9 | 194.8 | 173.3 | 209.7 | 234.1 | 209.7 | 273.1 | 320.4 | |

| Screw Revolution |

rpm | 0~350 | 0~300 | 0~300 | 0~280 | 0~280 | 0~250 | 0~250 | 0~240 | 0~240 | |||||||||||||||||||

| C l a m p i n g p a r t s |

Mold Clamping Foorce |

ton | 60 | 80 | 100 | 120 | 150 | 200 | 250 | 300 | 450 | ||||||||||||||||||

| max' Mold Plate Distance |

mm | 470 | 520 | 550 | 650 | 750 | 850 | 1000 | 1050 | 1200 | |||||||||||||||||||

| Clamping Stroke |

mm | 270 | 320 | 320 | 400 | 450 | 500 | 600 | 600 | 700 | |||||||||||||||||||

| Mold Thickness |

mm | 200 | 200 | 230 | 250 | 300 | 350 | 400 | 450 | 500 | |||||||||||||||||||

| Turn Table Diameter |

mm | Ø1000 | Ø1100 | Ø1100 | Ø1200 | Ø1400 | Ø1500 | Ø1500 | Ø1800 | Ø2260 | |||||||||||||||||||

| Ejector Stroke |

mm | 60 | 70 | 70 | 80 | 80 | 100 | 120 | 120 | 150 | |||||||||||||||||||

| G e n e r a l s |

Capacity of Main Motor |

kw | 11+3.5 | 15+3.5 | 15+3.5 | 18+5 | 22+5 | 30+5 | 33+5 | 33+7.5 | 50+11 | ||||||||||||||||||

| Capacity of Ejector Motor |

kw | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 5.5 | 5.5 | |||||||||||||||||||

| Capacity of Heater |

kw | 4.5 | 5 | 5 | 7 | 15 | 3.5 | 3.5 | 5.5 | 5.5 | |||||||||||||||||||

| Oil Tank Capacity |

L | 250 | 350 | 350 | 350 | 400 | 600 | 800 | 900 | 1100 | |||||||||||||||||||

| Machine Size (WxLxH) |

m | 1.23x2.25x2.27 (2.91) |

1.58x2.51x2.51 (3.01) |

1.72x3.08x2.49 (3.05) |

1.95x3.19x2.58 (3.13) |

2.08x3.28x3.19 (4.11) |

2.12x2.84x3.49 (4.46) |

2.40x3.54x3.79 (4.59) |

2.49x3.68x3.86 (4.83) |

2.54x3.68x4.50 (4.93) |

|||||||||||||||||||

| Machin Weight |

ton | 7 | 7.5 | 10 | 12 | 14 | 16 | 22 | 26 | 28 | |||||||||||||||||||

- Figures shown herein are subject to change without notice. Screw diameter and clamping force can be designed according to customer's needs.